Your engine's Pistons

Note: This content is directly from our Road Machines Educational CD, available for purchase and download instantly in our store.

Pistons:

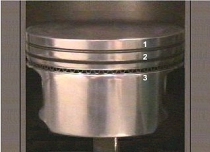

Pistons must be designed to withstand the high pressure and temperature generated during the combustion cycle. They must also be light weight to minimize loading on the connecting rod and crankshaft. To meet these requirements, pistons are usually made from cast aluminum. A set of three rings prevents the leakage of combustion pressure into the crankcase and oil leakage into the combustion chamber. Shown are the Piston (1), Valve Relief (2), Piston Pin (3), Pin Boss (4), Top Compression Ring (5), and Oil Ring (6).

Pistons must be designed to withstand the high pressure and temperature generated during the combustion cycle. They must also be light weight to minimize loading on the connecting rod and crankshaft. To meet these requirements, pistons are usually made from cast aluminum. A set of three rings prevents the leakage of combustion pressure into the crankcase and oil leakage into the combustion chamber. Shown are the Piston (1), Valve Relief (2), Piston Pin (3), Pin Boss (4), Top Compression Ring (5), and Oil Ring (6).

Piston Pins:

Two types of piston pins (3) are used in modern engines. The full floating pin is free to rotate in both the piston and the small end of the connecting rod. It is secured in place by snap rings which are fitted in grooves machined inside the piston's pin hole. The press-fit pin is free to rotate in the piston but not the connecting rod. The press-fit pin is very dependable and is the favored design.

Valve Reliefs:

Valve reliefs (2) are cast or machined into the piston's crown to ensure adequate clearance exists between piston and valves. The piston's upper surface is not always flat. Its shape is defined by the design of the cylinder head and combustion chamber. Pistons can be contoured with valleys and ridges.

Piston Rings:

Pistons have two compression rings (1 and 2) and one oil ring (3). The compression rings prevent blow-by, the leakage of combustion pressure into the crankcase. Ring tension and combustion pressure seat the rings in place creating a seal. The oil ring is designed to prevent crankcase oil from entering the combustion chamber. Its design is different than the others. Openings allow oil, scraped from the cylinder wall, back into the crankcase.

Pistons have two compression rings (1 and 2) and one oil ring (3). The compression rings prevent blow-by, the leakage of combustion pressure into the crankcase. Ring tension and combustion pressure seat the rings in place creating a seal. The oil ring is designed to prevent crankcase oil from entering the combustion chamber. Its design is different than the others. Openings allow oil, scraped from the cylinder wall, back into the crankcase.

Compression Ring:

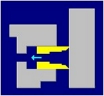

Compression ring tension (black arrow) closes the gap between the piston's outside wall and the cylinder wall. Combustion pressure (blue arrow) tightens the seal by applying a down force on the ring. This vertical force is also present during the compression stroke. A poor seal will result in blow-by, the leakage of pressure into the crankcase, which results in reduced power.

Compression ring tension (black arrow) closes the gap between the piston's outside wall and the cylinder wall. Combustion pressure (blue arrow) tightens the seal by applying a down force on the ring. This vertical force is also present during the compression stroke. A poor seal will result in blow-by, the leakage of pressure into the crankcase, which results in reduced power.

Oil Ring:

The primary purpose of the oil ring (3) is to prevent oil from leaking into the combustion chamber. Excess oil is scraped from the cylinder wall. Openings in the piston wall direct oil back into the engine's crankcase. Blue smoke exhausting from the tail pipe is an indication oil is leaking into the combustion chamber. Worn-out rings is one possible cause.

The primary purpose of the oil ring (3) is to prevent oil from leaking into the combustion chamber. Excess oil is scraped from the cylinder wall. Openings in the piston wall direct oil back into the engine's crankcase. Blue smoke exhausting from the tail pipe is an indication oil is leaking into the combustion chamber. Worn-out rings is one possible cause.